Feature

SD600G graphite machine center provides high-speed and precise graphite machining with a built-in spindle and designed plus-minus pressure system & excellent dust proof structure that prevents the inflow of graphite.

In addition, The SD600G has a fully enclosed splash guard that completely seals graphite dust inside to prevent dust leak out. Besides sealing graphite dust, dry machining of carbon fiber and brittle hard power metal is also possible.

Moreover, the low tooling wear and corner high acceleration deceleration make the graphite machining center more applicable to the needs of processors in today's market.

Not only that, SD600G won The National Brand Yusan Award in 2020, which means that the quality of our graphite machining center is performance and high quality for the customer to produce a wide selection of parts for industrial applications.

Below are the features of the SD600G graphite milling machine:

- A dry-cutting system makes sure dust easily collects. Non-environment pollution problems.

- All axes coverd telescoping cover to prevent ballscrew and linear guide way

- Strong negative dust suction system with a close full guard to prevent dust leaks.

- A positive pressure device in the electric box prevents the dust from entering the system.

- Continuous machining tolerances from large tool to small tool on surface below 0.01mm

- Corner rest machining can support up to dia. 0.2mm

- Machining surface can achieve accuracy of 85% from 3D data surfaces

- Machining time shorten by 30%

Specification

| Model | Unit | SD600G | |

|---|---|---|---|

| Control | CNC controller | Intek/Mitsubishi/Fanuc | |

| Travel |

X x X-axis/Y x Y-axis/Z x Z-axis | mm | 600/600/320 |

| Table top surface to spindle nose | mm | 80~400 | |

| Linear Guideway type (X/Y/Z) | mm | 45/45/45(THK-Ball type) | |

| Ball screw(X/Y/Z) | mm | Ø40/ Ø40/ Ø40 | |

| Table |

Table work surface area (X-axis x Y-axis) | mm | 600x600 |

| T-Slots (Size x Number x Centre) | 18x4x150 | ||

| Max. work piece weight | Kg | 500 | |

| Feed rate |

Rapid traverse rate X/Y/Z | m/min | 20/20/20 |

| Cutting feed rate | mm | 1-15000 | |

| Minimum input Increment | mm | 0.001 | |

| Spindle | Spindle holder | HSK-E40 | |

| Spindle motor | Kw | 4.6 | |

| Spindle speed | rpm | 24000/30000 | |

| Cooling Lubrication | Oil/Grease | ||

| A.T.C |

Tool magazine capacity | T | 24 |

| Max. tool weight | Kg | 1.5 | |

| Max. tool length | mm | 150 | |

| Tool selection | Armless | ||

| Motors |

X-axis drive motors | kw | 3.5 |

| Y-axis drive motors | kw | 3.5 | |

| Z- axis drive motors | kw | 3.5 | |

| Others |

Power | KVA | 20 |

| Pneumatic pressure | Kg/cm² | 6 | |

| Cutting pump | HP | 3/4 | |

| Coolant tank capacity | L | 250 | |

| Net weight | Kg | 6500 | |

| Floor space | mm | 2200x2700x2650 | |

Dust Collection system

| Motor | HP | 7.5HP TEFC |

| Air Flow | 2500FT³ ³/min | |

| Negative pressure | In/H2O | 1.26 |

| Max. negative pressure | in/H2O | 11.5 |

| Inlet | 8”x 1 holes | |

| Including | mm | ∅600mm x 600 |

| Machine floor space (L/W/H) | cm | 275 x 220 x 265 |

| Collector floor space (L/W/H) | cm | 120 x 120 x 260 |

The standard accessories of the SD600G graphite machining center

- CE mark electrical parts

- Organ-type stainless steel telescopic

- Tool change magazine

- Tool measurement devices

- Back flush device

- The second story type filter tank

- Built-in spindle

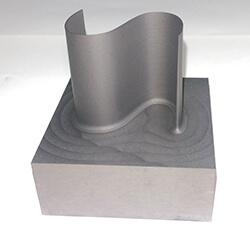

Sample

| Graphite Workpiece | |

| Total Machining Time |

2hr.35min |

| Workpiece Dimension |

450 x 80 x 80mm |

| Meterial |

GRAPHITE |

| No. of tools used | 6 |

| Process Time | |

| Total Machining Time |

7 min 22 sec |

| Meterial |

Graphite R8650 |

| Chips |

0.10mm |

| Size | 50 x 50 x 50 mm |

| No. of tools used | 3 |

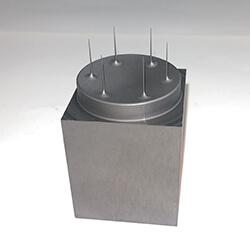

| Process Time | |

| Total Machining Time |

15min 37 sec |

| Meterial |

Graphite: R8650 |

| Chips |

0.10mm |

| Size | 30 x 30 x 25 |

| Pin | Ø 0.15 mm |

| No. of tools used | 3 |

| Chip 0.15mm

|

|

| Total Machining Time |

9 min 40sec |

| Meterial |

Graphite |

| Thickness | 0.15mm |

| Size | 50*50*50mm |

| No. of tools used | 1 |

|

Pin 0.15mm

|

|

| Total Machining Time | 7 min 10 sec |

| Meterial | Graphite |

| Pin | ø 0.15 |

| Height | 18mm |

| Size | 50*25*50mm |

| No. of tools used | 3 |