Feature

- High speed 0.65G (cutting)

- Perfect accuracy 12.3μ/10M/min( ball barΦ100mm)

- Spindle rigidity radial 12kg/μm~axial-8/kg/μm

- Low cutter wear -high acceleration/deceleration

- High speed function

- Continuous machining tolerances from large tool to small tool on surface below 0.01mm

- Corner rest machining can support up to Dia 0.02mm

- Machining surface can achieve accuracy of 85% from 3D data surfaces

- Machining time shorten by 30%

Specification

| Model | Unit | SD600 | |

|---|---|---|---|

| Control | CNC controller | Intek/Mitsubishi/Fanuc | |

| Travel |

X x X-axis/Y x Y-axis/Z x Z-axis | mm | 600/600/320 |

| Table top surface to spindle nose | mm | 80~400 | |

| Linear Guideway type (X/Y/Z) | mm | 45/45/45(THK-Ball type) | |

| Ball screw(X/Y/Z) | mm | Ø40/Ø40/Ø40 | |

| Table |

Table work surface area (X-axis x Y-axis) | mm | 600x600 |

| T-Slots (Size x Number x Centre) | 18x4x150 | ||

| Max. work piece weight | Kg | 500 | |

| Feed rate |

Rapid traverse rate X/Y/Z | m/min | 20/20/20 |

| Cutting feed rate | mm | 1-15000 | |

| Minimum input Increment | mm | 0.001 | |

| Spindle |

Spindle holder | HSK-E40 | |

| Spindle motor | Kw | 4.6 | |

| Spindle speed | rpm | 24000/30000 | |

| Cooling Lubrication | Oil/Grease | ||

| A.T.C | Tool magazine capacity | T | 24 |

| Max. tool weight | Kg | 1.5 | |

| Max. tool length | mm | 150 | |

| Tool selection | Armless | ||

| Motors |

X-axis drive motors | kw | 3.5 |

| Y-axis drive motors | kw | 3.5 | |

| Z- axis drive motors | kw | 3.5 | |

| Others |

Power | KVA | 20 |

| Pneumatic pressure | Kg/cm² | 6 | |

| Cutting pump | HP | 3/4 | |

| Coolant tank capacity | L | 250 | |

| Net weight | Kg | 6500 | |

| Floor space | mm | 2200x2700x2650 | |

Close

Standard Accessories

Standard Accessories

- CE mark electrical parts

- Organ type stainless steel telescopic

- Tool change magazine

- Tool measurement device

- Back flush device

- The second story type filter tank

- built –in spindle.

- full cover.

- blowing device for spindle.

- spindle coolant system.

- auto. Lubrication system.

- cutting oil coolant device.

- water Gun、side–way air blower,work lamp.

- hand-on type operation box / 26PIN hand wheel.

- RS232 9PIN INTERFACE.

- USB.

- heating box.

- auto. power of system+alarm lamp.

- basis bolt and adjusting screw.

- toolbox / operation manual/maintenance manual.

- high speed high accuracy function FTP system.

- Transformer

Sample

2017

video

| Process Time | |

|---|---|

| Total process time | 1hr1min 5sec |

| Material | NAK 80 HRC 38° |

| No.of tools used | 3 |

| Pin | Ø0.05mm |

| Size | 30 x30 x 25 mm |

2013

video

| Ball-Female | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 11E85 | CNC controller |

1 | 3000 | 9000 | 4m09s | |

| 12R2 | R2 | 2 | 2500 | 12000 | 2m59s | |

| 13R2 | R2 | 2 | 2500 | 12000 | 2m46s | |

| 14R1 | R1 | 3 | 1500 | 20000 | 29m35s | |

| Total : 39m29s | ||||||

video

| Ball-Male | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 21E85 | E8R0.5 | 1 | 4000 | 9000 | 8m38s | |

| 22R2 | R2 | 2 | 2500 | 12000 | 1m50s | |

| 23R1 | R2 | 2 | 2500 | 12000 | 3m27s | |

| 24R1 | R1 | 3 | 1500 | 20000 | 4m37s | |

| 25R1 | R1 | 3 | 1500 | 20000 | 27m38s | |

| Total : 46m10s | ||||||

video

| Direction of light 1 | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 31E8R05 | E8R0.5 | 1 | 3000 | 9000 | 5m10s | |

| 32R1 | R1 | 2 | 1500 | 18000 | 19m20s | |

| 33R75 | R0.5 | 3 | 1500 | 18000 | 10m23s | |

| 34R05 | R0.5 | 4 | 1500 | 20000 | 13m57s | |

| 35R03 | R0.3 | 5 | 1500 | 20000 | 1h21m41s | |

| Total : 2h10m31s | ||||||

video

| Direction of light 2 | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 61E85 | E8R0.5 | 1 | 4000 | 8000 | 6m22s | |

| 62R2 | R2 | 2 | 3000 | 13000 | 6m59s | |

| 63R75 | R0.75 | 3 | 2500 | 18000 | 26m11s | |

| 64R2 | R2 | 2 | 2000 | 16000 | 17m18s | |

| 605R75 | R0.75 | 3 | 2500 | 18000 | 15m17s | |

| 606R75 | R0.75 | 3 | 2500 | 18000 | 58m20s | |

| Total : 1h58m27s | ||||||

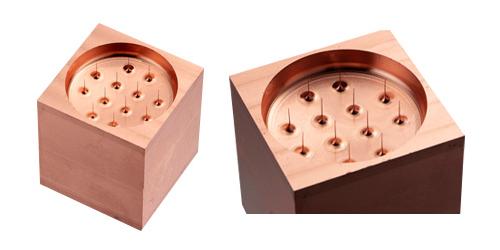

| Pin0.075D(Copper) | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 71E45 | E4R0.5 | 1 | 5000 | 12000 | 6m21s | |

| 72R15 | R1.5 | 2 | 4000 | 18000 | 8m29s | |

| 73R15 | R1.5 | 2 | 1000 | 20000 | 23m59s | |

| 74R75 | R0.75 | 3 | 1000 | 20000 | 3m01s | |

| 75R75 | R0.75 | 3 | 2000 | 20000 | 19m15s | |

| Pin Height : 5.75(4.03)mm/5.38(3.75)mm Total : 1h01m05s | ||||||

video

| Pin 0.05D | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 81E45 | E4R0.5 | 1 | 3000 | 12000 | 11m56s | |

| 82R15 | R1.5 | 2 | 4000 | 18000 | 23m04s | |

| 83R15 | R1.5 | 2 | 1000 | 20000 | 28m20s | |

| 28m20s | R1 | 3 | 2000 | 20000 | 3m48s | |

| 85R1 | R1 | 3 | 2000 | 20000 | 30m16s | |

| Pin Height : 4.9(3.45)mm/4.3(2.9)mm Total : 59m58s | ||||||

| Pin0.075D(Steel) | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 41E45 | E4R0.5 | 1 | 3000 | 12000 | 11m56s | |

| 42R15 | R1.5 | 2 | 4000 | 18000 | 8m29s | |

| 43R15 | R1.5 | 2 | 1000 | 20000 | 23m59s | |

| 44R75 | R0.75 | 3 | 1000 | 20000 | 3m01s | |

| 45R75 | R0.75 | 3 | 2000 | 20000 | 19m15s | |

| Pin Height : 5.75(4.03)mm/5.38(3.75)mm Total : 1h6m40s | ||||||

video

| Copper Electrode | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 91E85 | E4R0.5 | 1 | 8000 | 12000 | 3m40s | |

| 92R2 | R2 | 2 | 4000 | 16000 | 1m47s | |

| 93E8 | E8 | 3 | 3000 | 15000 | 16s | |

| 94E8 | E8 | 3 | 3000 | 15000 | 3m47s | |

| 3m47s | R1 | 4 | 3000 | 18000 | 1m33s | |

| 96R75 | R0.75 | 5 | 2000 | 20000 | 4m54s | |

| 97R75 | R0.75 | 5 | 2000 | 20000 | 20m05s | |

| Total : 36m02s | ||||||

video

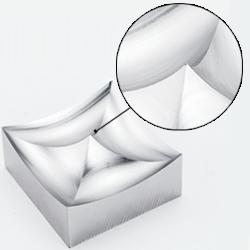

| Small Lampshade | ||||||

|---|---|---|---|---|---|---|

| Program name | Tool | Knife No. | FEED | RPM | Time | Note |

| 51E85 | E8R0.5 | 1 | 8000 | 12000 | 3m48s | |

| 52E85 | E8R0.5 | 1 | 4000 | 16000 | 43s | |

| 53E85 | E8R0.5 | 1 | 3000 | 15000 | 31s | |

| 54R1 | R1 | 2 | 3000 | 15000 | 14m15s | |

| 55R75 | R0.75 | 3 | 3000 | 18000 | 5m22s | |

| 56R05 | R0.5 | 4 | 2000 | 20000 | 14m17s | |

| 57R03 | R0.3 | 5 | 2000 | 20000 | 39m50s | |

| Total : 1h18m46s | ||||||

2011

video

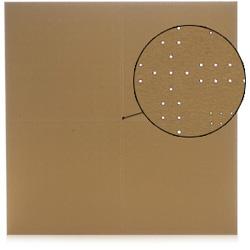

| 徵型鉆孔 | |

|---|---|

| Processing time | |

| Workpiece size | 400 x 400 mm |

| Hole diameter | Ø0.1mm ~ Ø0.3mm |

| Workpiece material | S45C |

| Number of tools | |

| 手機模仁 | |

|---|---|

| Processing time | 3hr. 52min. 25sec |

| Workpiece size | 50 x 115 x 30mm |

| Workpiece material | STAVAX |

| Number of tools | 8 |

video

| 尖塔 |

|

|---|---|

| Processing time | 37min. 36sec |

| Workpiece size | 50 x 50 x 25mm |

| Workpiece material | SKD61 HRC-45 |

| Number of tools | 3 |

| 測試件 | |

|---|---|

| Processing time | 1hr. 3min. 15sec |

| Workpiece size | 50 x 50 x 25mm |

| Workpiece material | NAK-80 HRC380 |

| Number of tools | 1 |

| Working Deepth | 2mm Ø0.6m |

video

| 車燈 |

|

|---|---|

| Processing time | 4hr. 32min. 10sec |

| Workpiece size | 100 x 76 x 50mm |

| Workpiece material | NAK-80 HRC-38 |

| Number of tools | 4 |

video

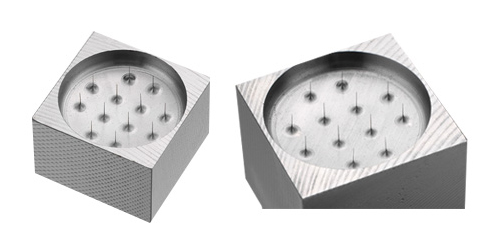

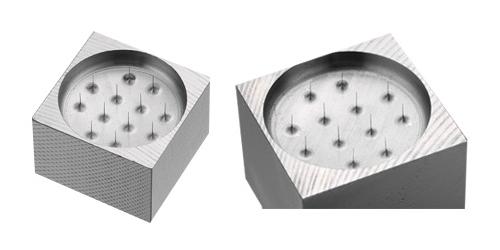

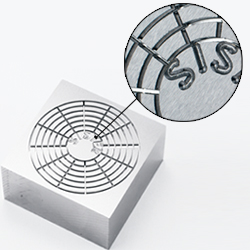

| 測試件(劍山) | |

|---|---|

| Processing time | 1hr. 3min. 15sec |

| Workpiece size | 30 x 30 x 25 |

| Workpiece material | NAK-80 HRC-38 |

| Number of tools | 1 |

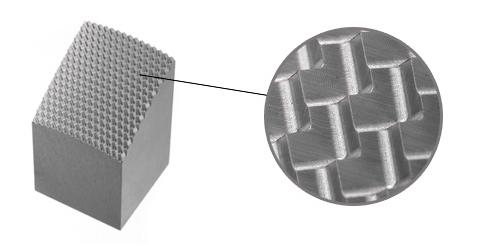

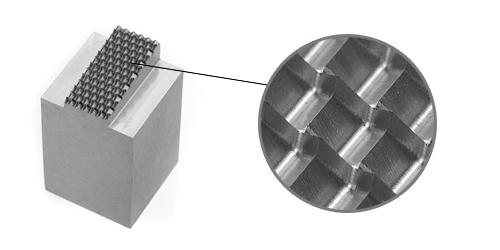

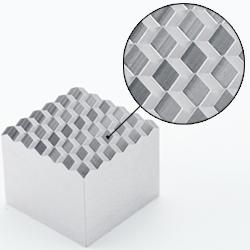

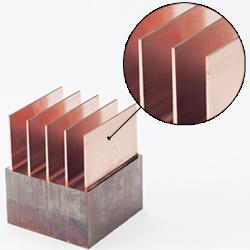

| 肋片(Lib) | |

|---|---|

| Processing time | 4hr. 30min. 27sec |

| Workpiece size | 40 x 44 x 44mm |

| Workpiece material | Copper |

| Working Deepth | 25mm |

| Number of tools | 2 |

| 數位相機 | |

|---|---|

| Processing time | 4hr 25min |

| Workpiece size | 100 x 60 x 25mm |

| Workpiece material | AL6061-T6 |

| Number of tools | |

video

| Copper-watch | |

|---|---|

| Processing time | 38min. 54sec |

| Workpiece size | 50 x 50 x 50mm |

| Workpiece material | Copper |

| Number of tools | 8 |

video

| NAK80-watch |

|

|---|---|

| Processing time | 54min . 15sec |

| Workpiece size | 50 x 50 x 50mm |

| Workpiece material | NAK80 |

| Number of tools | 8 |

video

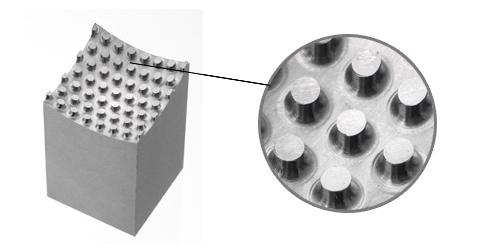

| Pin |

|

|---|---|

| Processing time | 51min. 55sec |

| Workpiece size | 25 x 25 x 25mm |

| Workpiece material | NAK80 |

| Number of tools | 2 |