Feature

- A fixed work table designed to easily put down and take out work piece

- High speed 0.65G (cutting)

- Perfect accuracy-18μ/10M/min

- Low cutting wear high acceleration/deceleration

- A double Y axis drive moving it’s not effected by cutting torque to make error movement

- A double Y axis is driven by dual servo motors &feed system each single feed system of Y axis is separately compensated

- A regular value drive torque for three axes moving designed it’s not affected by weight of the work piece during cutting.

Specification

| Item/model | unit | SD1085 | |

|---|---|---|---|

| Control | CNC control | INTEK 470 | |

| Spindle motor | KW | 11KW(15KW,18KW0 | |

| Motor of three axis (x.y.z.) | KW | 3.5/3.5*2/3.5with Break | |

| Taper of spindle | BT40(HSK-A63,HSK-E50) | ||

| Spindle | Spindle drive | Built-in | |

| Spindle speed | RPM | 15000(2000,30000) | |

| Table size | mm | 1100*900 | |

| Table | T-slot(Width*No.*Pitch) | mm | T16 |

| Table load | KG | 1500 | |

| Travels | Travel for X*Y*Z axis | mm | 1000*800*500 |

| Distance from Spindle nose to work table | mm | 150-650 | |

| Center of spindle to z-axis slide-way | mm | 310 | |

| Feed rates | Rapid feed rate | mm/min | 20000 |

| Circle cutting accuracy | mm | 0.01 | |

| Cutting feed rate | mm/min | 20000 | |

| Min. resolution | mm | 0.001 | |

| Tool | Max. tool length (Diameter) | mm | 200(32) |

| Max. tool weight | KG | 4 | |

| ATC tool magazine (arm–less type) | T | 20(24option) | |

| Power sources | Spindle coolant-power/oil capacity | Watt /Liter | 750/8 |

| Auto. Lubrication system –power/ oil capacity | Watt/Liter | 220/2 | |

| Heating system / hose | watt | 40*2 | |

| Capacity of Cutting fluid box | L | 180 | |

| Compressed air supply | Kg/cm2 | 6 | |

| Power | kW | 25 | |

| Weight | Machine net weight | KG | 9300 |

| Machine gross weight | KG | 9950 | |

| Machine size | Packing size( L/W/H) | cm | 3215*2280*2500 |

| Floor Space of machine(L/W/H) ) | cm | 3330*4110*3020 | |

Close

Accessories

Accessories

Standard accessories

- built –in spindle.

- full cover.

- blowing device for spindle.

- spindle coolant system.

- auto. Lubrication system.

- cutting oil coolant device.

- water Gun、side–way air blower,work lamp.

- hand-on type operation box / 26PIN hand wheel.

- RS232 9PIN INTERFACE.

- USB.

- heating box.

- auto. power of system+alarm lamp.

- basis bolt and adjusting screw.

- toolbox / operation manual/maintenance manual.

- high speed high accuracy function FTP system.

- Transformer

Optional Accessories

- spindle : 20000/30000rpm.

- auto. Chip conveyer.

- oil separation.

- Auto. tool length measuring device

- Oil Mist Collectors

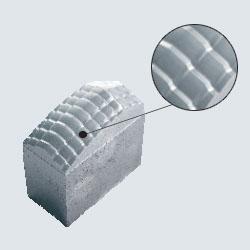

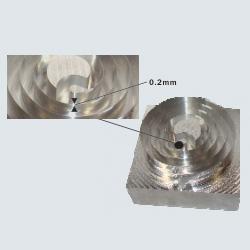

Sample

| Total Machining Time | 2hr.11min.25sec |

| Material | NAK-RO HRC-38 |

| Workpiece Dimension | 50 x 100 x 100mm |

| No. of tools used | 3 |

| Total Machining Time | 18min. 21sec |

| Material | AL6061 T6 |

| Workpiece Dimension | 150 x 150 x 100mm |

| No. of tools used | 1 |