Feature

- The integrally finished Meehanite casting utilizes annealing and abrasive machining to ensure precision and stability.

- The X, Y, and Z axes are all fitted with heavy-duty roller-type linear guideways, featuring low stick-slip and low friction coefficients. This allows for high feed rates and precise positioning accuracy.

- A high-rigidity, wide-range column with integrally finished casting design enhances machining capabilities in various cutting conditions.

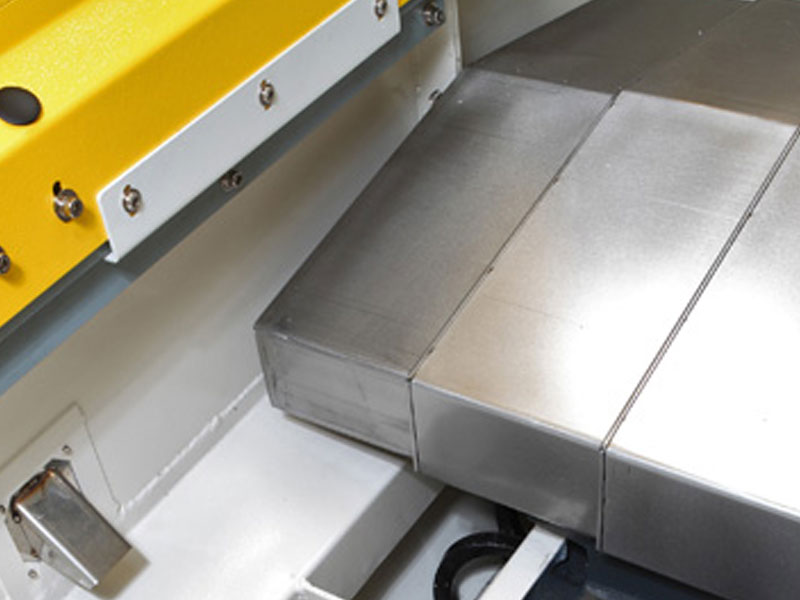

- A chip auger is installed at the front of the base, designed to deliver chips out of the machine and prevent chip accumulation.

- Specially designed for high-speed cutting of hardened metals and tough machining applications.

Specification

| MODEL | Unit | SV6H | |

|---|---|---|---|

| controller | Mitsubishi/ Fanuc | ||

| Motor |

x-axis motor |

kw |

1.5 KW |

| Y-axis motor |

kw |

1.5 KW |

|

| z-axis motor |

kw |

525 | |

| Spindle |

Spindle Motor (Con./30 min) |

Kw/HP |

5.5/7.5(7.5/11) KW High /Low Winding Switching |

| Spindle taper |

BT40 /HSK |

||

| Spindle type |

Direct drive |

||

| Spindle speed | 10000/ (12000, 15000, 30000) opt. | ||

| Table |

Table size |

mm |

750*450 |

| T-slot (Width*No.*Pitch) |

mm |

16*3*125 |

|

| Max. work piece weight |

kg |

200 |

|

| Travel |

X/Y/Z axis Travel |

mm | 650/400/500 |

| Spindle Nose to work distance. Min- Max. |

mm |

120~620 |

|

| Spindle Center to Column surface distance |

mm | 525 |

|

| Linear Guide type X/Y/Z |

mm |

30/30/35 |

|

| Cooling / Lubrication |

Oil/grease |

||

| FEED RATE |

Rapid traverse x/y/z |

mm/min | 30/30/24 |

| Cutting feed rate |

Mm/min | 1-10000 |

|

| Min. Resolution |

mm | 0.001 |

|

| Tool |

Max. tool Length |

mm |

300 mm |

| Max. Tool diameter | mm |

∅77(127) |

|

| Max. tool weight |

Kg |

7 |

|

| Tool selection | Random | ||

| Tool magazine arm type | capacity | 24 | |

| Other |

Coolant tank capacity |

L |

180 |

| Pneumatic pressure |

Kg/cm |

6 | |

| Coolant motor power |

HP |

3/4 |

|

| Thru spindle coolant |

290Psi(20bar) |

||

| Machine size | Machine net weight | kg | 3400 |

| Floor space of machine | mm | 1980*2400 | |

| Power | KVA | 25 | |

*Specifications are subject to change without prior notice.

Close

Accessories

Standard Accessories

- Heat exchanger.

- Removable manual pulse generator(MPG).

- Enclosed splash guard & Top guard.

- FTP& RS-232 interface & USB(Intek).

- Automatic power off.

- Screw type chip conveyor.

- Automatic lubrication equipment.

- Work light & Alarm light.

- 9.3 Axis telescopic cover.

- Wash gun / Air gun.

- Swing type operator panel.

- Spindle oil cooler.

- Chip augers on base.

- Rigid tapping.

- Bed coolant wash.

- Tool kit.

Optional Accessories

- Flat type chip conveyor and chip bin.

- 2.4th, 5th axis control and rotary table.

- Coolant through spindle with filter.

- Automatic tool length measuring device.

- Linear scale.

- 30T